- Seen : 617 View

One of the most common ways to protect reservoirs, pipelines and fittings, metal structures and bodies of ships against corrosive environmental agents, is coatings with paints, resins and insulators. Having a proper level, clean and free of any kind of alarm to carry out the necessary cover.

For cleaning small surfaces, grinding, sandblasting, brushing and brushing techniques are being carried out in its large commercial dimension, sandblasting or shot blasting.

Shot blast operations are mainly carried out to achieve two goals:

1. Removing and removing foreign masses and rust and reaching the metal surface

2- Create appropriate metal roughness at the metal surface for better adhesion of the coating film to the shield

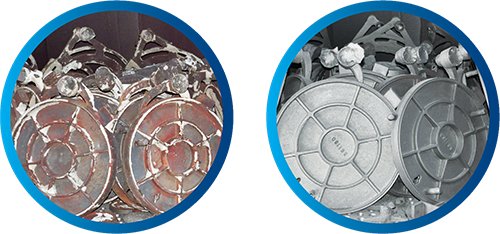

In this technique, steel balls (spherical and broken) or steel shot and shotgun are accelerated using compressed air or turbine, and are generally thrown onto metal surfaces.

Continuous impact of steel balls In this technique, rigging, sand making from casting, dyeing, deforestation, forging, shot pinning, and denting of industrial components allow the execution of rust removal operations.

The main spray system is the Wheel Blaster turbine blast shotgun, which provides industry-class cost savings for its users.

Saler Company Information