- Seen : 215 View

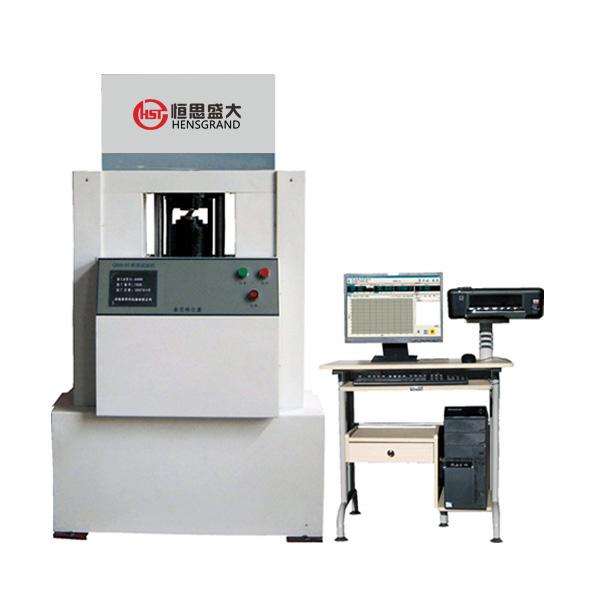

The Cupping testing Machine ( Erichsen Tester ) is precise technology testing machine which is used for sheet metal & strip steel rolled stock etc. It can complete test of plastic deformation for sheet metal & strip steel rolled stock .

Standard:

It conforms to ASTM E 643-78 & GB4156-84 named Testing Machine for Metal Cupping test

Feature:

1, Computer control operation, according to the preset program and data, automatic clamping, stamping, measurement, calculation, parking

2, Auto stop when crack appears, convenient to observe the crack;

3, With computer controlled the test, user can easy get test report, and save, recall, print test result;

4, Turnover grips, punch and sample is easy to change;

5, With peak value memory function, like max. punch load, max. deformation deep etc;

6., Adopting a composite oil cylinder can meet hydraulic clamp and press piston and cylinder;

Specification:

Model

GBW-60B

Specimen thickness

Standard 0.1-2mm,( Non-Standard 0.1-3mm)

Max. Specimen Width

100mm

Max. Punch stroke

60mm

Clamping piston stroke

19-21mm

Max. Cupping Force

60kN

Max. Clamping Force

25kN

Test mold specifications (Standard)

Punch diameter:Φ20±0.05mm,cushion mold hole diameter : Φ33±0.1mm

Fixed mold hole diameter: Φ27±0.05mm

Standard press mold hole diameter : Φ27±0.05mm; ( Non-Standard )

Test mold specifications (Non-Standard)

Punch diameter : Φ15±0.05mm , Φ8±0.02mm, Φ3±0.02mm

Press mold hole diameter : Φ18±0.1mm, Φ10±0.1mm ,Φ3.5±0.1mm

Fixed mold hole diameter : Φ21±0.02mm ,Φ11±0.02mm , Φ5±0.02mm

Display resolution

0.01mm

Saler Company Information