- Seen : 782 View

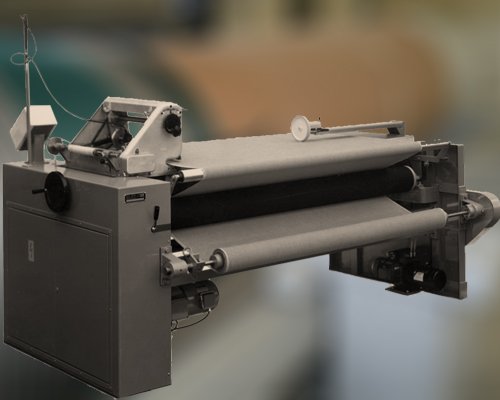

The fabric is opened by the feed roller by the pull roller and then wrapped on two guide rollers that shine together. Next, move on to the next tensile roller that is positioned before the fabric wraps.

Printing occurs between two roller bearings and that part of the fabric on which printing is to be stopped momentarily is done simultaneously with pressure.

While the fabric movement of the feeder roller, traction roller and retractor roller continues to rotate, this ensures a smooth and smooth machine operation.

The printer machine uses the flat type printing, whereas the copy machines have regular letter printing systems. The need for engraving is therefore no specific mold compared to rotary machines.

This feature dramatically increases the versatility of this machine and meets the specific needs of customers.

The maximum printing length (8.5 ° C) is 22 cm and the height (32.25 °) is 2 cm.

This printing machine is electrically heated, and since different textiles and foil require different temperatures, the printer is equipped with a thermostatic heat control element that is set by a thermometer. This feature allows the operator to choose the right temperature for any situation.

The foil is fed automatically by the roller. Foil opening and closing rates can be adjusted to eliminate waste depending on print height. For cleaning and checking, all of these parts can be opened without the use of any tools with just a few simple hand movements.

With a simple adjustment the machine can be set to print on any one, two, three meters or yards.

At a very low cost, the machine can be equipped with additional gears, which also make it possible to print per unit of yardage. To ensure proper printing on the sides, the printer, operated by an optical sensor, automatically moves along the edge of the fabric.

Saler Company Information