- Seen : 219 View

Standard:Test method accord with European standard EN13900-5:2005 test standard.

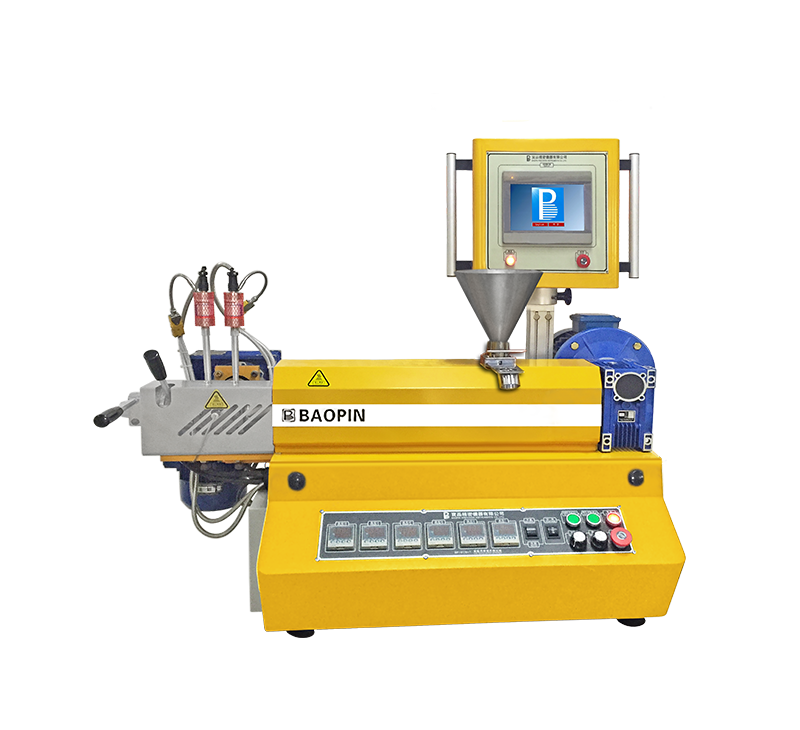

一、Single screw extruder

1、Screw diameter:20mm

2、Length diameter ratio:1:25

3、Screw material:It is made of 38CrMoAlA chromium-molybdenum steel. With the surface-layer processing of tempering, nitriding, chroming, polishing and super-precision grinding, the hardness HRC55~60, roughness Ra≤0.4μm, nitriding depth≥0.6mm.

4、Barrel material:It is made of 38CrMoAlA chromium-molybdenum steel. With the surface-layer processing of tempering, nitriding, chroming, polishing and super-precision grinding, the hardness HRC55~60, roughness Ra≤0.4μm, nitriding depth≥0.6mm.

5、Heated zone:Mica heater in 3 area of charging barrel, heater in 2 area of handpiece. Each area has a copper cooling fin covered with security wind shield.

6、Cooling device:Three groups of multi-wing fans to cool air quietly and strongly

7、Screw speed:0-95rpm frequency speed controller

8、Melt temp:Dynisco high precision temperature sensors to monitor the melt temperature change

9、Quick change device:C type snap ring connection, easy to quickly connect with the downstream equipment.

10、Electronic control system:PLC programmable color touch screen, man-machine interface operation system, can dynamically display and monitor extrusion process, including temperature control, driving, pressure, interlocking spreading function.

11、Power:3∮,AC380V,50Hz three-phase five wires

12、Dimension:850×450×650 (W×D×H)mm

13、Weight:About 125kg

二、Metering pump

1、Output:2cc/rev thoughput capacity

2、Rotation speed:60rpm transducer adjust

3、Temp:≤350℃

4、Pressure:≤270bar

5、Pressure sensor

6、Inlet pressure:0-10Mpa(Dynisco)

7、Outlet pressure:0-35Mpa(Dynisco)

8、Pressure accuracy:within ± 0.1%

三、Filter net

1、Screen standard reference EN13900 -5:2005, aluminum frame, for the European standard screen - pack1 / pack2 / pack3 model size.

四、Program controller

1、PLC color touch programmable controller, man-machine interface operation system.

2、Including pressure, temperature, flow rate control module, which can interlock spreading and closed-loop control.

3、Timely collecting and capturing every moment melt temperature and pressure change curve.

4、With USB interface, can connect the printer print test results.

5、Automatically generating test reports, automatically computing filtration pressure value (FPV).

Saler Company Information