- Seen : 107 View

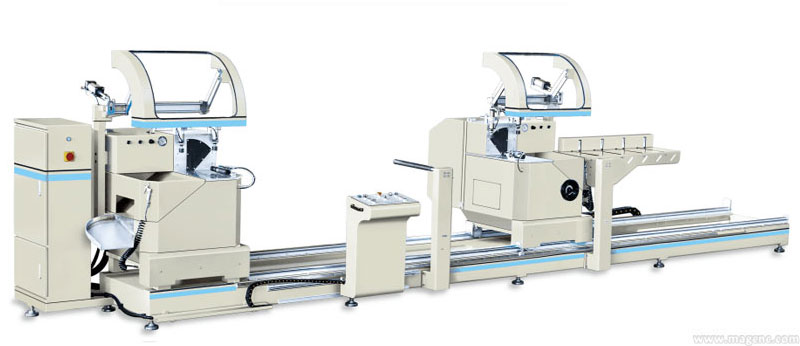

1). It is mainly used for processing of extra-wide aluminum profile, 650mm high quality carbide tipped saw blades.

2). High precision main shaft to keep saw blades running stability.

3). Lathe bed adopt steel structure welding and through aging treatment to avoid bed deformation .

4). The two saw head independent swing angle,adopt cylinder driving,setup inside angle that is 45° 90°.The diameter of saw blade is 650mm to realize large end face profile cutting.

5). Movable saw head adopt pneumatic measuring locking fine tuning appliance..

6). At the middle of bed equip with two sets of independent pneumatic up-down auxiliary supporting frame. Movable saw head connects with profile conveyor, make the profile be fully in stable condition.

7). Movable saw head moving adopt roller structure, by turning movable hand wheel to make the head move flexibly and portable

8). Vertical and horizontal clamping cylinder. Profile clamping adopt three position clamping structure, all these can be controlled independently.

9). The cutting angle by two saw head can be arbitrary combined, like left head 90°, right head 90°;left head 45°, right head 90°;left head 45°, right head 45°;left head 90°, right head 45°

10). Spraying cooling system. Safety protection system, heavy duty unibody steel construction.

11). CNC system and display system can be put in, it can make the cutting much more precise, and the operating more visualized.

Saler Company Information