- Seen : 605 View

Application: Absorption of vibration and unwanted movements in pipelines and ducts

Description: Dynamic equipment in the pipelines including pumps, compressors, fans, turbines, etc. Due to internal movement, they apply vibrations to the pipeline, which cause the noise, early demolition of the pipeline and other parts, and There are many other problems.

The use of rubber shimmers is one way to prevent the transmission of vibrations to other parts of the pipeline. One of the most common uses of rubber shimmer in the Suction and Discharge section of pumps is that in addition to absorbing existing vibrations, the ability to remove ram blows and shocks. Other uses of rubber vibrations are more suitable for use in corrosive environments than accordion joints. Although these connections tolerate limited temperature and pressure.

Occasionally, a rubber shimmer is used to prevent electrical conductivity.

The following are some of the uses of rubber shimmer:

chemical industry

Marine industries

Installations Industries

Food industry

steel Industries

Oil, Gas and Petrochemical Industries

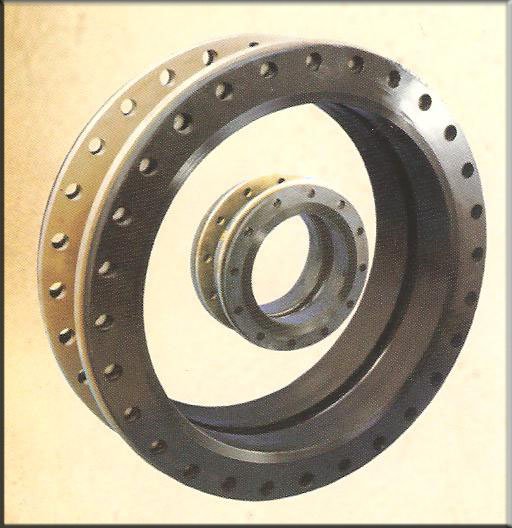

Types of rubber shaving rings manufactured by Iran Vibration Industrial Company

1- Low-level flush-mounted magnets: The production of this type of vibrator is from a size of (1 to 12 inches) and is commercially available with BL-72 and AESA brands. These parts are made using rubber and metal muscles, and bake with electric heaters.

2. High-resolution magnets: The production of this type of vibrator (¼1 to 140 inches) is known as the brand of autoclave seismic. The inner parts of the inner muscle are used to make these pieces and the baking process is carried out inside the autoclave boilers.

Advantages of rubber seals:

Resistance in cycles of fatigue and failure

Resistance and vibration-free vibration

Return to deformation and deformity

Resistance to electrical stresses

High flexibility against shock and shock

High mobility and flexibility at low distances

Simultaneous axial and lateral movements

No need for internal guide (in Filled Arc connections)

Sound capability

No need for gaskets and seams

Reduced thermal dissipation

The ability to deform with low force and thus applying low power to equipment

Low weight and ease of installation and replacement

• Technical Specifications: Rubber shimmers are manufactured with various materials for different working conditions (temperature, fluid and environmental conditions), details of each type are described in detail in the relevant catalog.

Saler Company Information