- Seen : 418 View

Glass is one of the most important building materials that should be considered fire safety. In order to understand the importance of glass and its role in fire distribution, fire behavior and fire safety engineering must be considered.

The behavior of a fire in a closed space, and more specifically a room, depends on the entrances to that room. An even small volume fire requires high oxygen levels to spread.

The window and the only oxygen inlet are from the outside into the interior (until the ceiling and walls have collapsed). If used in the window structure, ordinary glass will break the glass up to 2 or 2 degrees Celsius as the temperature rises. In this case, the fire spreads without delay. The ordinary glass that is secured also does not differ much in performance from ordinary glass as it breaks down into small, non-woven parts.

When the temperature of the fire reaches 2 to 5 degrees Celsius, the entire interior burns in a very short time (such as an explosion), causing the remaining pieces of broken glass to fall out of the window and oxygen to burn. At this time, the rate of fire growth depends on the area of the window and the volume of fire. If the area of the window is low relative to the amount of fire, airflow is limited, and when the fire is inadequate, its growth rate is low. Of course, this does not mean less danger or easier control of the fire. In contrast to the heat of the interior of the fire, it causes chemical decomposition of the objects in that space. As a result of the decomposition, combustible gases are released and fill the available space. But because of the lack of oxygen, these gases do not burn, as the volume of hot gases increases, the gas pressure in the room rises and erupts out through broken windows. As soon as these gases are thrown into an oxygen-filled environment, they start burning and as a result, the flame flies out of the window through the window and catches fire.

If there is no problem with oxygen deficiency, flammable gases will burn with all the objects in the room. In this situation the flames do not fire but smoke is emitted.

Let's not forget that the casualties and fatalities in fires are not only through burns. Rather, high temperatures and suffocation play a role in increasing mortality rates.

The above illustrates the important role of glass in the spread of fire. Safety of glass not only helps prevent the fire from developing, but also provides the opportunity for residents to escape and even collect valuable items.

The performance of firefighting glass is primarily related to maintaining the integrity of the glass during a fire. The criterion for evaluating this performance is based on the following three criteria:

Maintain Integrity (E)

Maintain Integrity and Limit Emissions of Hot Gases (EW)

Integration and Thermal Insulation (EI)

These criteria are expressed in the acronym in front of them. The length of time that the glass retains its integrity and function is expressed as a number next to the letters, such as EW 60, a fireproof glass that retains its integrity for 5 minutes, during which time the speed of the hot gas is transmitted. Reduces and actually gives residents a 5 minute escape time.

Maintain Integrity (E)

This criterion indicates the ability of glass to prevent the passage of smoke and smoke.

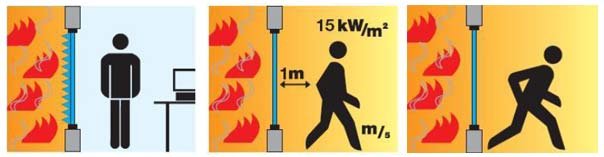

Maintain Integrity and Control Hot Emissions (EW)

In this situation, more time will be created for the escape of residents with higher safety. At the same time maintaining the integrity of the glass, hot gases pass less slowly through the glass surface and the temperature of the adjacent space increases at a slower rate.

Integration and Thermal Insulation (EI)

It works best in fireproof glass which can keep the adjoining space safe and cool for a certain period of time. In this situation, the glass will not only retain its integrity for a sufficient time, but will prevent the spread of hot and hot gas.

Securified wired and bursilicane glass are in the first or E group. Wired or opaque glass are only light transmitted but boron and silicate glass are as transparent as ordinary glass.

Glasses that are laminated with special coatings fall into the second and third category. They are normally transparent and do not differ much from other laminated glass, but as a result of fire, they expand and become a matte and hard shield. This feature reduces the heat transfer through the glass and allows for a smooth discharge.

When an intumescent layer of laminate is laminated with glass, this glass falls into the second group, but when two or more layers of laminate fall between three or more layers of glass, the laminated glass falls into the third group. Depending on the number of layers, these jars can generate between 1, 2, 3 and 5 minutes of escape time.

So residents can finally collect the peace and quiet of even precious things and then evacuate the place. They can be used in window, door, ceiling and partition structure.

Depending on the type of glass used in their structure, these types of laminated glass also have the following characteristics:

Heat resistant

Soundproof

Resistant to impact, attack and theft

Solar Control

Resistant to throwing broken glass pieces

Saler Company Information