- Seen : 858 View

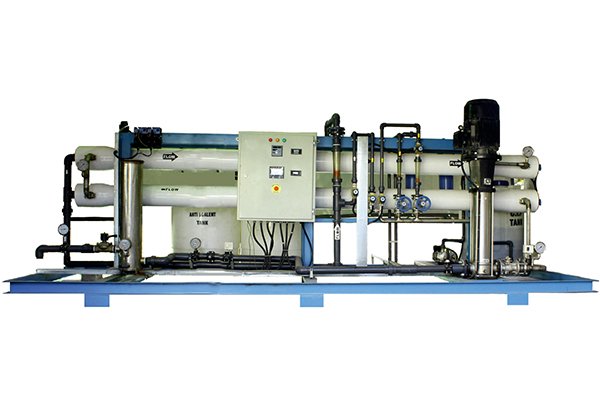

Desalination (reverse osmosis)

Reverse osmosis is a process in which pressure is used to reverse the osmotic flow of water through a semipermeable membrane. If a semi-permeable membrane is placed between two solutions of pure water and impure water, water flows naturally and under osmotic property from a lower concentration to a higher concentration. This phenomenon will continue until the chemical potential of the two sides is equal. At equilibrium, the pressure difference between the two sides of the membrane is equal to the osmotic pressure difference. If a pressure equal to the difference in osmotic pressure is applied to the thicker solution, the water flow will be cut off. If the applied pressure is higher than the osmotic pressure, it will be reversed to the normal flow of water.

High-performance reverse osmosis systems use pressures of up to one million Pascals. Also, the best method for desalination of brackish water is to use the reverse osmosis process because it does not have a complex system and its management is more controllable than other methods. Today's industries make extensive use of reverse osmosis systems to purify the water used in their steam generation and process sectors. The work of these devices is based on the passage of non-ionic molecules such as water through a membrane with very small pores. These membranes are designed to allow neutral molecules to pass through easily. For this reason, the water entering the system, which contains different salts, is converted into almost pure water. In a reverse osmosis system, the inlet or feed stream is converted into two streams of treated water and concentrated effluent.

Membrane selection:

In reverse osmosis system, membrane is the most important and sensitive part of the device because the required operating pressure is directly related to the thickness of the membrane and the diameter of its holes. Also, the membrane should be resistant due to constant contact with chemicals added to water and should not react with inhibitors, anti-fouling agents and biocides.

Factors influencing membrane comparison include:

1- Diameter of holes

2- Thickness

3- Resistance to chemicals

4- Price

5- Pressure drop

6- Manufacturer

The water must be pre-treated before entering the reverse osmosis device.

Preliminary treatment:

Effective pretreatments for feed water are essential. The purpose of this step is to help increase the operating time of the membranes. Choosing the right pre-treatment makes the flow intensity and product quality at the highest efficiency.

Water desalination system components (reverse osmosis):

1- High pressure pumps

2- Pressure chamber

3- Membrane

4- Control tools and valves

5- Barometers

6- Flowmeter (flowmeter)

7- Guidance meter

8- Valves

9- flashing system

10- CTP washing system

11- Control panel

12- Chassis

Date

July 25, 1398

Tags

Water purifier

Saler Company Information