- Seen : 356 View

A chiller is a device that uses refrigerant gases to take the temperature of the environment to be cooled and transfer it to the outside environment. In order to buy a chiller, the price of the device must first be reported to Mehtab Gostar colleagues by knowing the capacity and type of compression cycle requested by the employer.

What is a chiller?

Residential, commercial and industrial units use cooling and air conditioning systems to dehumidify and cool the building. Chillers have become integral components of cooling and ventilation systems for a wide range of commercial buildings including hotels, restaurants, hospitals, sports arenas, industrial plants and manufacturing units.

In terms of performance, chillers are considered as the most optimal air conditioning devices, which are one of the important factors in optimizing the energy consumption of a production unit or building. In general, chillers are devices that help transfer heat from the indoor environment to the outdoor environment. Heat transfer in this device is based on the process of distillation and evaporation of a refrigerant that is circulating between the chiller components.

In fact, chillers are used as the beating heart of cooling systems by cooling a fluid (mainly water) with a refrigerant fluid such as freon gas with the aim of cooling the air inside the building by industrial devices such as air conditioners and fans or cooling industrial devices or machinery.

How the chiller works

Based on the refrigeration cycle, chillers cool the water needed for cooling commercial or industrial units and pump it through a pump to the air generator or cold air distribution units such as fan coils. The cold water flowing inside the coils of the air conditioner or fan coil causes the temperature of the coil to decrease, and the temperature of the air passing through these coils also decreases, and by circulating in the space of the commercial or industrial unit, it causes environmental cooling.

The way the chiller works is different based on the division of chillers based on different factors.

Types of chillers based on the type of refrigeration cycle

Chillers are divided based on different parameters. Chillers work based on the principles of condensation or vapor absorption.

Below is a summary of the water de-heating process in chillers in each condensation and absorption refrigeration cycle.

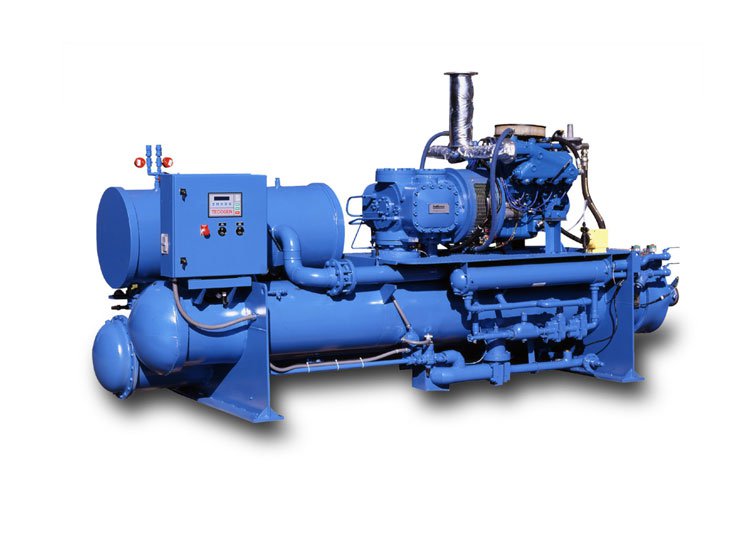

Compression chiller

In this case, the water cooling process in the chiller is based on the condensation refrigeration cycle. The refrigeration cycle has four stages: 1-evaporation 2-vapor condensation 3-distillation 4-expansion.

Compression chillers are a simple refrigeration cycle that includes four main parts: compressor, condenser, evaporator and expansion valve. The refrigeration cycle begins with the introduction of low-pressure refrigerant into the evaporator in two-phase mode.

At a constant temperature, the refrigerant vaporizes by taking heat from the environment or hot water entering the evaporator and cools the ambient air or hot water entering. Then, the low-pressure gaseous refrigerant is sucked and condensed by the compressor, and its temperature and pressure increase.

In the next step, this hot gas with high pressure is directed to the condenser or condenser by the hot gas pipe, and by passing through it at a constant pressure, it loses its heat and becomes a hot liquid with high pressure. Then this refrigerant liquid passes through the expansion valve and encounters a pressure and temperature drop and enters the evaporator and performs the process of cooling the ambient air or water and this cycle is repeated.

Saler Company Information