- Seen : 397 View

Today, there is an urgent need for compressed air in the production industry. A lot of money is spent to provide this power. And stopping the flow of compressed air in the production will cause the production wheels to fail, and the importance of choosing a high quality compressor will involve the production process.

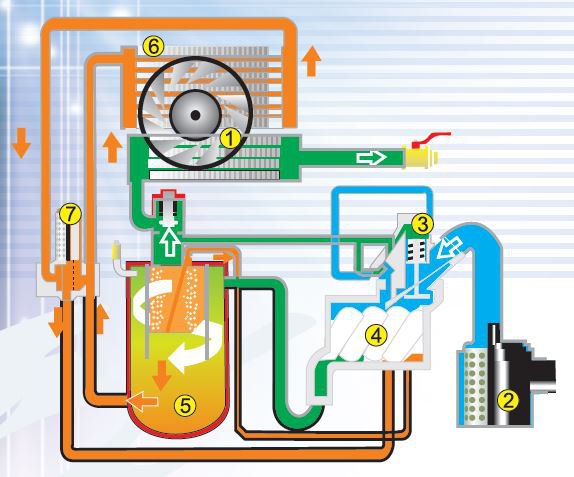

The air enters the device through the cooling fan, through the E3 norm pre-filter (1) and reaches the cassette model air absorption filter (2). The filtered air goes to the pneumatic inlet valve with compressed air) is controlled; guided (3) then reaches the iron part (4) and is compressed. At the same time as the air is compressed and released by two asymmetric helical rotors, oil enters the iron. The oil prevents the contact of two At the end of the compression process, a mixture of oil and air enters the oil separation tank (5), the oil is separated from the air in the amount of two to three milligrams per square meter during the separation process in three stages. Air and hot oil enter the radiators. A combination of oil and air is cooled (6). The cold compressed air then enters the machine, and the oil returns to the machine after being filtered (7).

air conditioning unit:

The basis of the operation of the compressor is the air generator unit, so using the best air generator unit with high quality and efficiency will make a durable compressor with a longer lifespan.

power transmission :

The power of the electric motor is transferred to the air conditioner unit by the belts, which are adjusted by the automatic belt tensioner and have the following advantages.

1- Increasing the life of the belt and preventing premature corrosion of the belt

2- Transmission of maximum power with minimum slippage of the belt on the pulley

3- No need to tighten the belt and save time to replace the belt

Propulsion :

The main power of starting the compressor is the electric motor. The engines used by this company are manufactured by reputable European companies.

Cooling system:

The use of aluminum aftercooler with 40 bar test pressure and 26 bar working pressure and equipped with a propeller and a separate electric motor for better cooling and directing the hot air inside the couch to the outside and prevents the temperature increase inside it and the aftercooler temperature The compressed air brings the output from the compressor to about 5 degrees Celsius higher than the ambient temperature, and the oil cooler provides a long life for the oil and oil filter by providing the right temperature.

Sound intensity :

The appropriate design of the machine body and the optimal arrangement of the parts inside the compressor and the use of sound insulation significantly reduce the sound intensity and eliminate the need to install and use the compressor in a separate room, and the use of high-quality shock absorbers prevents the transmission of any The type of vibration of the compressor during operation and completely eliminates the need for a foundation.

Intake air adjustment valves:

The inlet air adjustment is equipped with two systems, Proportional and Load-Unload, which selects the load-unload system, the required pressure for the no-load mode of the device for easy oil circulation, and the additional air inside the receiver automatically in the no-load mode after The under load is discharged and by maintaining the required pressure for oil circulation and discharge of the load behind the main engine for restarting.

Quick installation:

Due to the design and installation on the Flexble mounting system, the compressors of this company do not need a special foundation and they have oil on delivery and are ready to start easily. You only need to connect the compressor to the electricity and turn it on. Despite the ease of installing and setting up the device, our specialists are always at the service of our dear customers and do the installation and setting up for free.

Service and maintenance:

The use of modern and high-technique equipment and the proper arrangement of parts inside the device increases the lifespan and efficiency of the compressor, and by providing timely and fast after-sales services by the experienced technicians of this company with a regular periodic schedule, it reduces costs. service and maintenance, and minimizes the compressor downtime for each service.

Overview of AR1210 control system

A) Screen:

* 20*4 LCD screen

* Has eleven signal lights to display the status of the device

* 7 keys to use the screen

b) Control board

* Has seven output relays for control

* With unloader triac control

* 3 analog inputs (two pressure and one temperature)

* Features of the AR1210 system

* Ability to control the main engine (triangle star)

* The ability to control an unlimited number of electronic unloaders

* Permanent storage of information (registering operator parameters)

* Accurate pressure calibration

* Has two pressure sensors from 4 to 20 milliamps

* It has an internal clock to measure the lifetime of parts separately

* It has a weekly program to turn the compressor on and off automatically

* Declaring system errors separately

* Announcement of device service time

* Ability to restart the device in case of sudden power failure

* Display the internal temperature of the device

* Notification of temperature increase errors can be adjusted

* Ability to apply limits for maximum pressure and maximum temperature

* Measurement of device load time and total device operation time

* The ability to set the internal timers of the device as internal timer software

* Ability to select and delete digital or analog inputs

* Has an analog output to control the inverter

Saler Company Information