- Seen : 466 View

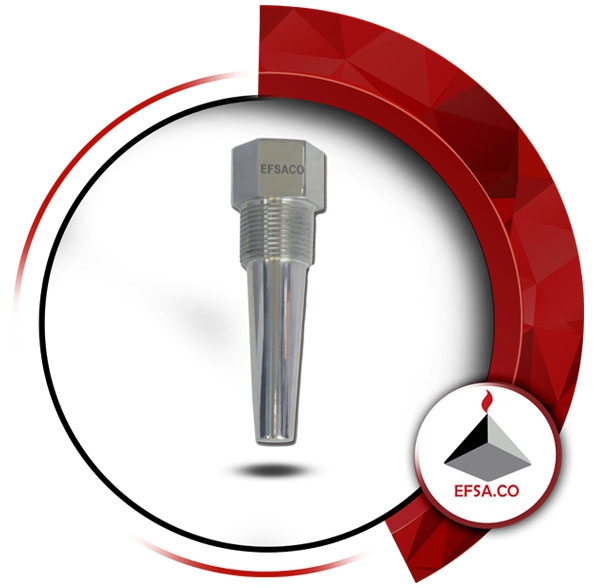

The remover is used to protect the temperature sensor against the harsh conditions of the process and the ability to remove the sensor from its place without stopping the process. Although at first glance, Thermowell seems to be a simple device, but its proper selection requires the determination of several parameters.

The parameters that each of them should be specially selected to have the least adverse effect on the measurement accuracy, the least need for repair and maintenance, and as a result, reduce and eliminate the risks caused by damage to the Thermowell.

Types of thermowells

They are divided into three categories in terms of shape.

Stepped: Considering that the stepped type has a lower time constant than the other two types, it is used when we need a quick response.

Straight:

Tapered (funnel-shaped) or conical: due to its structure, the conical type has a higher resonant frequency than the straight type with similar dimensions. Therefore, it is a suitable choice when the speed of the fluid passing through the pipe is high. It is recommended for velocities More than 5 M/S in liquid fluids and 15 M/S in gas fluids should use conical thermowell. The IPS-C-IN-120 standard also emphasizes the need to use the conical type when the fluid velocity is more than 21 M/S. emphasizes. At lower speeds, if the direct thermowell does not pass the stress analysis, the use of the conical type can be a solution to pass

stress analysis.

Thermowell material

The materials that are usually used in the construction of Thermowell are: different grades of stainless steel, chrome-molybdenum steel, silicon bronze, monel, nimel, titanium, etc.

Failure to choose the correct type and shape of the thermowell causes incorrect measurement or its destruction, which may cause irreparable accidents. Therefore, the ASME-PTC 19.3 standard has been presented to ensure the durability of thermowells in the harsh conditions of complex chemical processes. Also, in choosing thermowells, the design conditions and standards of the piping site should also be taken into consideration. Thermowells are generally made by machining a single round metal section (Round Bar Stock) and one end of it is prepared to connect to the piping plant in one of the forms of welded thermowells, threaded thermowells or flanged thermowells. This is while protective tubes are not necessarily machined and it is possible to make them in other ways. For very high temperatures, materials such as ceramic or silicone should be used to make Thermowell and protective tube.

Saler Company Information