- Seen : 819 View

Hardening performance Most of the time the treated water contains mineral salts and soluble salts and is not completely pure. Water hardness is primarily related to calcium and magnesium compounds and to a lesser extent to other high capacity metal ions such as iron, manganese, aluminum, etc. One of the major problems caused by the use of hard water in the industrial sector is the formation of sedimentary layers in heat exchangers, boilers and cooling towers.

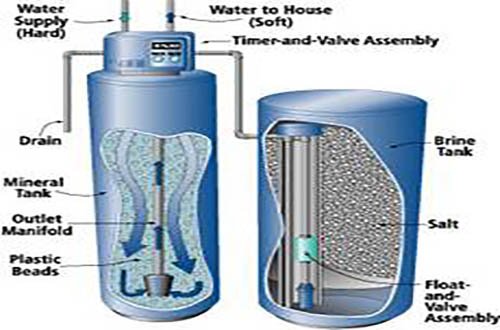

The creation of sedimentary layers is mainly due to inadequate heater performance, higher energy consumption, increased maintenance costs, maintenance and operation, corrosion of facilities and pressure drop. One of the most effective methods for eliminating water hardness is the use of hardening resin systems. In these systems, the hard water passes through the resin bed of the hardened tanks, exchanges its calcium and magnesium salts with the existing sodium, and the soft water is removed from the system. Due to the hardness of the water as well as the design, the system is reconstituted with sodium chloride solution before the resin is completely saturated.

Some benefits of water hardening and softening in the industrial sector:

Maintain optimal performance and increase efficiency of heating systems, boilers and cooling towers

Increase the useful life of pipes

Reduction of sedimentation and wall clogging of the facility

Reducing corrosion and eliminating plumbing in buildings

Reduce system running, maintenance and repair costs

Better performance of service systems such as laundry and car washes

Detergent saving

Major application of resin hardening systems in water supply industries: Oil, gas and petrochemical industries, power plants, refrigeration systems, boilers and heat exchangers, textile and dyeing industries, food industry, pharmaceutical industry, livestock and poultry industries, factories Manufacture of ceramics, cold stores, hotels and restaurants, laundry facilities, car washes

Main Components of Automatic Hardening Systems

1- Resin tank: Includes resin substrate for ion exchange and removal of water hardness generating solutes and sand substrate for retaining resin substrate

Salt Tank: To produce the brine needed to restore the system

3. Filter cap including timer for automatic control

Specifications of Absan hardeners:

Ability to withstand smooth body pressure up to 5 times

Body material of the highest quality fiberglass FRP / carbon steel with inner coating of three layers of epoxy and outer coating consisting of a stainless paint layer and an oil paint layer

Resin supply of high quality resins with high exchange capacity and stability

Featuring standard lenses and up and down viewing lenses

Equipped with water dispenser and water collector made of PVC resistant materials

Equipped with polyethylene salt tank to restore the system

System capability to be fully automatic, semi-automatic and manual

Equipped with proper plumbing

Equipped with air valve, drain valve and manometer

Saler Company Information