- Seen : 329 View

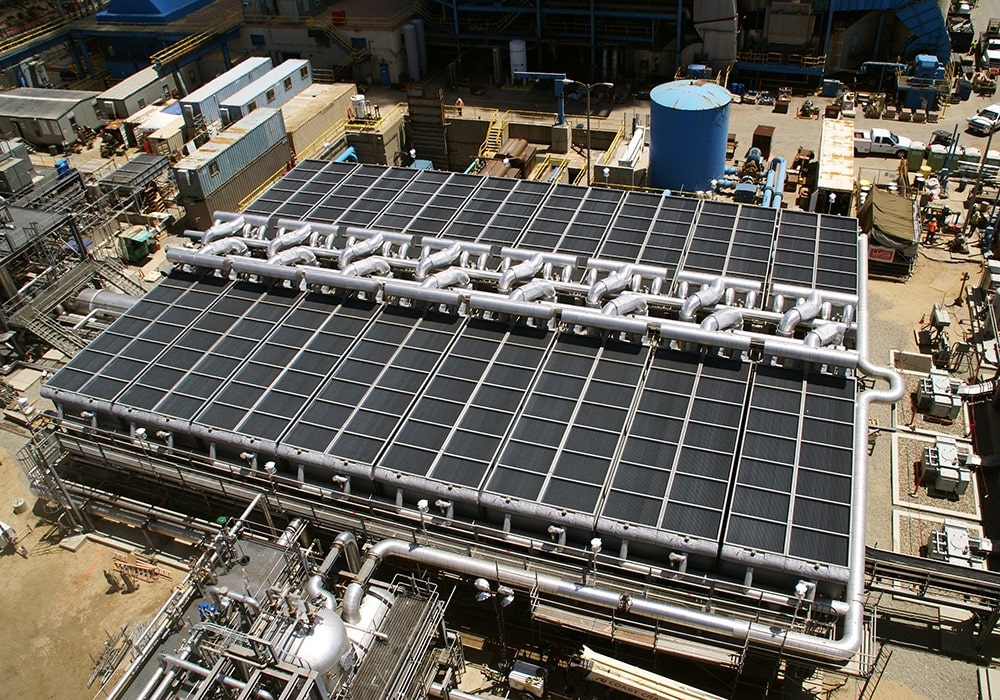

Air-Cooled Heat Exchanger is a very widely used type of heat exchanger that works based on heat transfer between fluid and air. This type of converter is indicated by the abbreviation ACHE and is one of the cooling tower equipment in industries. These types of exchangers are among the most widely used heat exchangers in industries. In areas where it is not possible to provide water as a source of cooling or it is expensive, the best and first option to provide the required cooling is to use air-cooled heat exchangers (air coolers).

In this converter, heat is received from a fluid and then released into the air. Of course, regarding the operation of this type of heat exchanger, there is a big difference between releasing heat to air and transferring heat to water. This exchanger is also used as a shell and tube heat exchanger in the cooling tower in refineries and petrochemical industries.

One of the most important and main advantages of using air-cooled heat exchangers in industrial processes is that these exchangers do not need water; This sentence means that industrial projects with high cooling capacity do not need to be built near water sources for cooling. In fact, an air-cooled heat exchanger can play the role of cooling processes as an air cooler.

What parts does the air-cooled heat exchanger consist of?

The air-cooled heat exchanger consists of one or more different surfaces in a batch for heat transfer; In this type of equipment, there is also an air cooling device like a fan. If the blades of this cooling fan move naturally, they are strong enough to activate the air cooler system in the air-cooled heat exchanger, but in cases where it is not possible to move the fan automatically, they move it mechanically.

In the air-cooled heat exchanger, some supporting structures are built in to keep the parts inside the exchanger stable; There is a specific part in these converters that allows the inspection of different parts or its repairs. There is another part in the above converter through which the temperature conditions can be controlled.

The rectangular plates inside the air-cooled heat exchanger are placed in several rows next to each other and provide a special path for the fluid to pass and facilitate heat transfer. The air-cooled heat exchanger is actually a counter-flow exchanger. The hot fluid enters the bed from the top of the heat exchanger and the air flows vertically upwards under it. In this way, heat is exchanged between fluid and air.

In fact, in this air-cooled heat exchanger (air cooler), the hot fluid is distributed in a set of tubes that are placed horizontally together, and the heat transfer process takes place simultaneously with the passage of ambient air through the walls of the tubes.

The level of heat transfer between the fluid inside the tubes and the cooling air is increased by installing special fins on the outer wall of the tubes.

Air-cooled heat exchangers are cross-type in terms of flow shape, and the air flow required to cool the fluid inside the tubes is provided by a fan. If this fan is placed above the pipes, it is called suction, and if it is placed below the pipes, it is called blowing.

Saler Company Information