- Seen : 288 View

High build quality

Absence of swelling and water absorption compared to wood

Good thermal properties

Good thermal properties due to low coefficient of thermal expansion

A product with high mechanical capabilities

Suitable mechanical properties such as mechanical strength, impact resistance and fatigue

No design restrictions

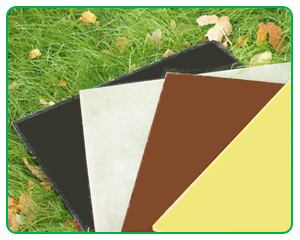

Ability to produce sheets in standard sizes, dimensions and different colors

Resistant to chemical fluids

High resistance against alkaline and acidic fluids

Fire resistant

High fire resistance due to additives

Good dimensional stability

The dimensions of composite sheets remain constant under mechanical load (even in a long period of time).

Application of composite sheets in different industries

Chemical and petrochemical industries

With the correct selection of raw materials, the resistance of GRP sheets can be increased against chemicals, fire and other environmental factors. This feature along with other unique features of GRP makes it possible to use these sheets in various chemical and petrochemical industries.

construction

The ability to produce GRP sheets in different dimensions and colors, very light weight, ease of drilling, ease of cutting and installation, fire resistance, waterproofness, makes possible the use of these sheets in covering the roof of all kinds of structures.

Water and sewage industries

High strength-to-weight ratio, easy installation, and high corrosion resistance make GRP sheets ideal for use as weir plates, water flow control valves, and water storage tanks.

Electronic industries

Compared to common engineering materials such as steel, aluminum and wood, GRP composites have the advantages of electrical insulation, light weight and corrosion resistance. These properties bring applications for GRP composite sheets including the manufacture of cable trays and accessories, ladder rails, electronic enclosures, communication tower components.

The high mechanical resistance of composite sheets and the possibility of using them along with corners, cans and other forms of composites has given this unique opportunity to industries and industrialists to design, produce and repair their products. The easy cutting and forming of composite sheets and the possibility of producing some of them in non-sheet form has made it possible to produce unique final products. The possibility of connecting composite sheets to other composite products through cold welding has provided the possibility of future updates for products produced from composite sheets.

Saler Company Information