- Seen : 429 View

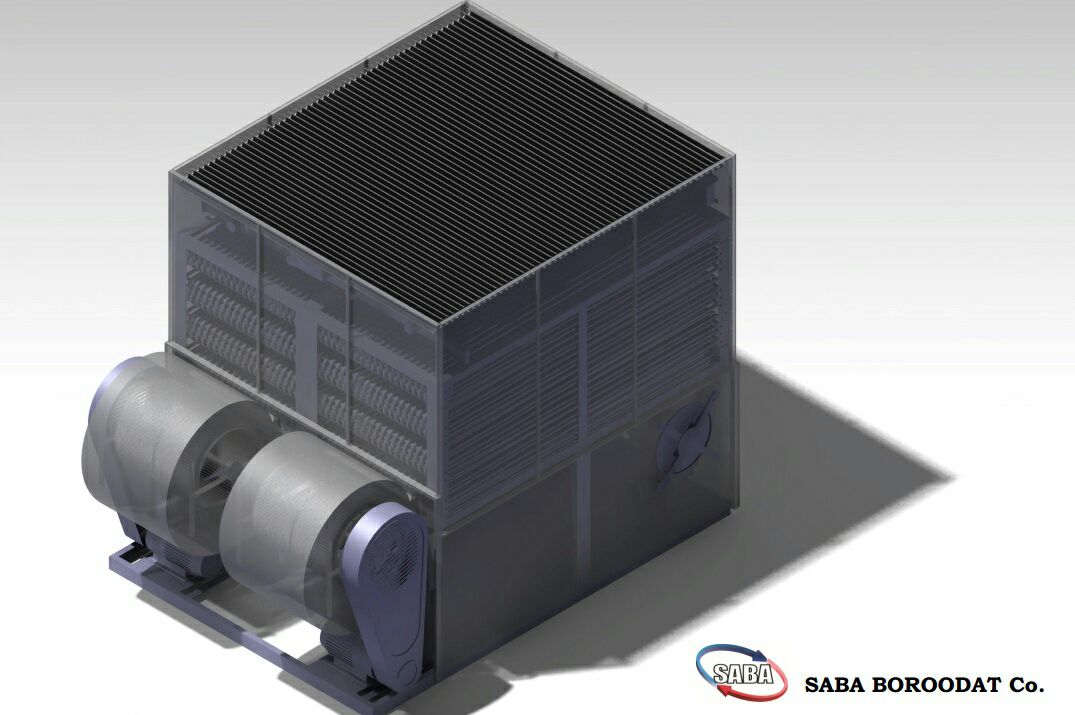

Condensers of Saba Brodt Pars Company are produced under ASHRAE standard. Different types of industrial condensers are produced in Saba Brodt Pars Company, which meet all the needs in the country.

more details

Saba ECL model evaporative condenser is manufactured in 39 standard models and in different capacities from 89Kw to 4885Kw. These condensers can be used in ammonia, freon systems and industrial closed circuit systems to cool water or other carrier solutions (Fluid Cooler). Each condenser consists of two separate parts, the coil and the pan, which makes it very easy to transport and install. Saba evaporative condensers are made for a useful working life with maximum capacity, low depreciation and easy service and maintenance. The presence of abundant and cheap spare parts, various accessories (such as D-super heater, multi-speed fans, condenser capacity control system, multi-circuit coils, etc.), five-year warranty and after-sales service make Saba condensers unrivaled.

Attributes

The number and total ventilation of the fans have been selected based on accurate calculations and in accordance with the climatic conditions of Iran, the most important advantage of which is the saving of less energy consumption, less wear and tear, and the long life of electrofans.

In the design of the new Saba condensers, the set of fans are considered outside the pan, which makes the air hit all the surfaces of the coils and we have counter flow of air and water in all the coils.

The dimensions of condensers and condenser parts and components have been completely standardized for ease of manufacturing and sales support services.

The total water circulation in ECL condensers has been optimized, which significantly saves the amount of water consumed.

All electric motors have IP 54 class F protection or IP 55 upon request.

All inlet, outlet, overflow, etc. connections are optimized for maximum efficiency.

All components of ECL condensers are hot galvanized according to the ASTM A123 standard with a thickness of 60 to 100 microns.

All coils of ECL condensers are hydraulic pressure tested at a pressure of 32 atmospheres.

Condenser coils are charged with nitrogen gas before delivery to the customer.

The nozzles of the water distribution system on the coil are made of PVC and specially designed by Saba Broodt Company.

The required industrial heater along with the relevant thermostat is included in the machine pan.

The coil is made of API5L steel pipe with an external diameter of 26.7 mm according to DIN 2394, which is hot galvanized to 80-100 microns after 32 atmospheres of pressure test.

Bending of coil pipes is done by a special machine without double width of the pipe and all the welding related to the coil is done by CO2 welding machine. At the same time, bending is done integrally and U-bends are not used.

The design and construction of the coil causes a minimum pressure drop in the refrigerant circuit, as well as the fluid discharge of the refrigerant liquid and oil from the inside of the coil.

Saler Company Information