- Seen : 933 View

Application:

The system is designed to automatically and continuously adjust the fat in the milk and cream as soon as you exit the separator. This system allows the automatic adjustment of fat in daily milk, cream, flavored milk, fermented milk, cheese milk, ice cream mix, formulated and powdered products.

work Principles:

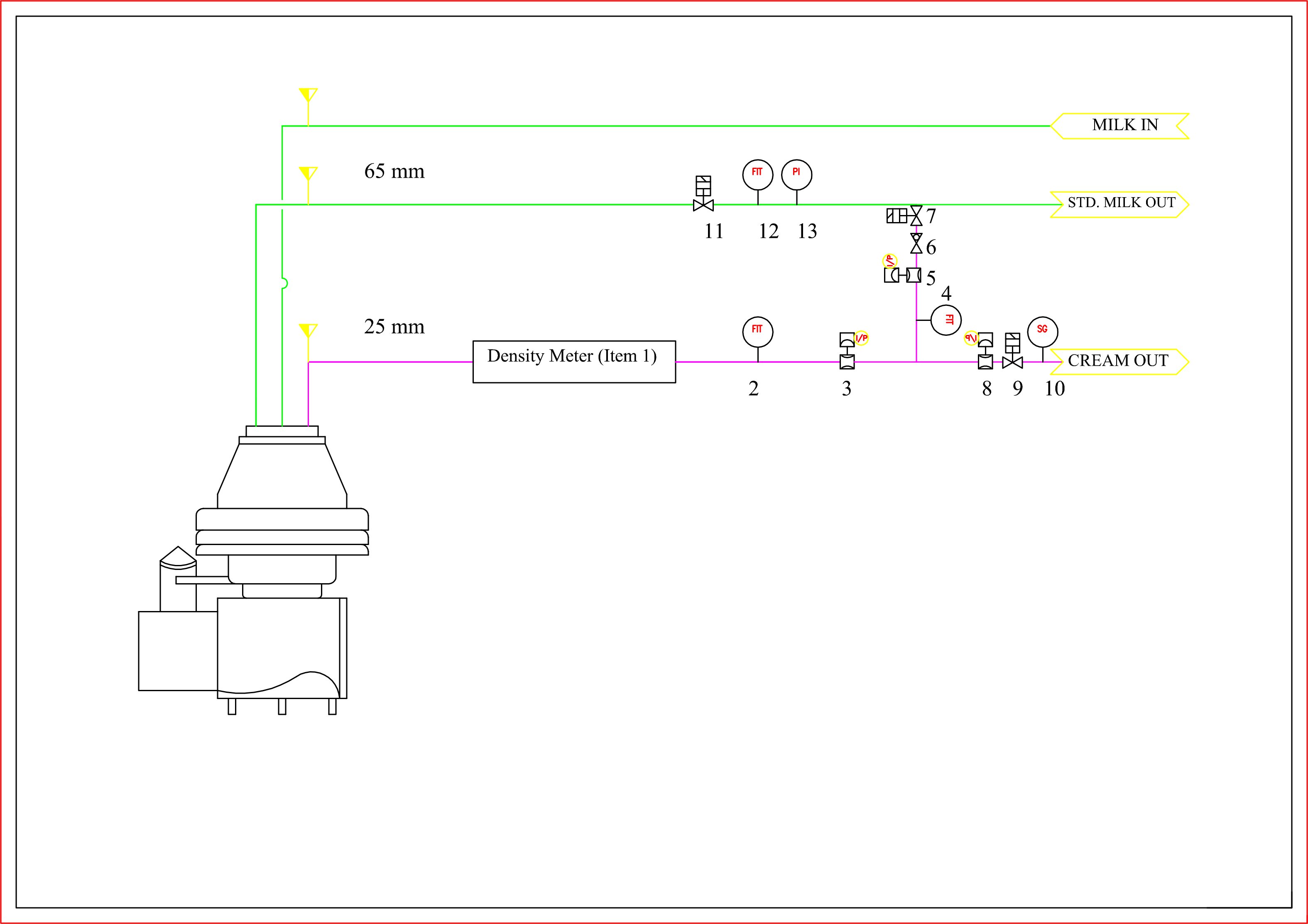

The system continuously controls the cream pressure by means of a constant pressure valve at the system output through a Cascade controller, thereby carefully controlling the percentage of cream fat output. The rear wheel valve exits the separator and the pressure at the system outlet is stabilized by constant pressure valve. An electromagnetic flowmeter measures the cream discharge output from the separator and the cream fat percentage is measured continuously by a density meter. Another flow meter measures the standardized milk flow rate. When the desired percent of cream output is applied to the device, the density meter first measures the fat percentage and gives the creamer control valve the necessary instructions to stabilize the fat percentage. When the desired fat percentage is applied to the standard valve on the machine, the machine calculates the amount of cream to be added to the skim milk and instructs the output control valve to reach the desired fat percentage.

Model:

FSN FSU 1 with capacity of 50000 Lit / hr

Main components:

- Densitometer Online

- Electromagnetic flowmeters

-Barometer

-Stainless steel control panel including PLC and HMI

- Dubai control valves

-Automatic butterfly valves

- chassis and associated pipe and fittings

-The cables and trays of the respective cables

Control system:

PLC: Siemens S7 300

HMI: Touchmaster touch panel

Process parameters:

Dubai Raw Milk: Capacity of 5,000 liters / hr

Inlet temperature of milk: C 65-45

Dimensions:

mm 1720x 1050 x 1120 (length x width x height)

Options:

- Ability to automatically calibrate SNF changes

- Ratio control (Fat / Protein) and Fat / SNF

- By the way of the separator

- Standardize fat to C-1-3

-Remove the separator partially

-Online sensor to measure fat ratio of finished product

Advantages of FSN FSU 1 System:

- Same quality of output product

- High accuracy in fat standardization

-Reduce investment (no need for tanks and other extras to standardize fat)

-Flexibility in producing finished product with different fat percentage

- Very low chance of human error

- Less consumption of chemicals and other contaminants compared to tanks and other extras for standardization

- Quick return on initial investment due to the above

Saler Company Information