- Seen : 363 View

The gasketed plate heat exchanger was invented in the 1930s for use in the food industry, especially the dairy industry. Gradually, with the optimization of the components, parts and manufacturing methods of this type of heat exchanger, from the 1960s onwards, the conditions for their use in other industries were prepared.

One of the most important factors in expanding the use of plate heat exchangers with washers in other industries is the improvement of plate geometry, the development of raw materials and their more efficient design.

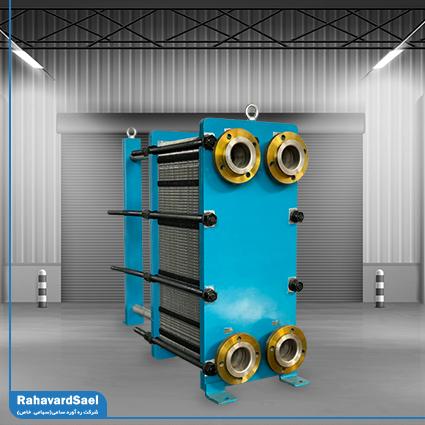

The most important part of a gasketed plate heat exchanger consists of a number of thin metal sheets with a wavy surface. Each plate is separated from the next plate using a rubber piece called a washer, and finally, a "gasketed plate heat exchanger" is made by placing a set of plates and washers between two thick plates and pressing them together with a number of fastening screws.

The role of metal sheets is to create temperature exchange surfaces and the function of gaskets is to seal the temperature exchange surfaces to each other and also to the surrounding environment of the plate heat exchanger.

The special arrangement of the temperature exchange surfaces and washers, together with the place where the fluids pass in the corners of the plates, creates conditions that allow the movement of hot and cold fluids through the channels created by the plates, alternately and alternately.

Types of plate heat exchangers

Gasketed plate heat exchanger

The plate heat exchanger with washers is one of the types of plate heat exchangers in which polymer washers are used to seal the plates. The set of these plates are tightened by bolts and nuts between two steel frames, and this is why it is also called a framed plate converter.

The operation of the gasketed plate heat exchanger

The way to arrange the plates of the gasketed plate heat exchanger is in such a way that it creates a honeycomb network. This network is actually the path of movement of hot and cold fluid. The way the plate heat exchanger works is that two fluids enter the heat exchanger from nozzles in opposite directions and leave it after transferring heat. The hot and cold fluid plates are placed side by side.

In fact, the fluids that enter these corrugated plates flow in the form of one in the middle between the metal plates and perform heat exchange operations with each other. These plates are placed symmetrically behind each other and hot and cold fluid circulates between these plates. The arrangement of the surface of the plates causes waves in the fluid, and in this way, the process of heat transfer and cooling of the temperature between two fluids will be done at a high speed.

The operation of the gasketed plate heat exchanger as well as its structure is such that it is possible to easily access its internal components. This point has made it easy to clean, maintain and maintain this type of converter. Creasing of the plates will increase the disturbance of the fluid flow. This is the reason why the rate of heat transfer increases and as a result the heat efficiency of the converter also increases. How the plate heat exchanger works

Saler Company Information