- Seen : 304 View

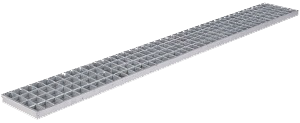

Grating is a type of steel or fiberglass mesh that has properties

Such as high resistance, the possibility of passing light and air, beautiful appearance and lower price

to similar options as one of the most widely used choices for coverage

The floor (walk way) and stairs of factories and urban buildings are known.

Grating or metal mesh plates are produced using belts or bars.

For example, belt grating in belt, belt grating in rebar

Belt grating is woven in four sides, which is the most widely used

It has belt grating in the rebar.

Load bearing belt: A belt that bears the incoming load and on the supports

placed on both sides.

Interface (belt, rebar or four-sided): It is installed in the direction perpendicular to the bearing belts

Its task is to maintain the spring of this product and not to distort its geometric shape.

Spring (meshbandi): The distance between the bearing belts and the interface is said to be from each other.

which is usually specified by two numbers: x*y. The first number x is the distance between

load belts and the second number y is the distance between the interfaces.

All sizes are in millimeters according to the ISO standard.

Advantages of using grating products

This product has easy installation and low cost compared to other products.

In different weather conditions and under the force caused by any type of foreign body

It is resistant and durable.

No need for repairs during operation, light weight and extremely high strength

is also one of the advantages of this product.

This product is a non-slip and safe product

And for this reason, it is used in huge projects

And it is also suitable for making stairs and steps.

The beauty of the grating and its strength against corrosion and no need for cleaning

Its level is one of the things that can be mentioned.

Meanwhile, if galvanized grating is used, this galvanized coating

It will make the product more resistant and unnecessary for painting.

One of the most important steps in the production of this product (of any type) is its design

which is done by the technical engineering unit.

The design of this product is usually done by the employer companies.

In this way, they map the location of the grating

And they design it according to the executed structure or from accuracy

And the accuracy of the production process of the structure or the tank according to the production plan, full confidence

have and design them according to the designed maps.

In fact, compared to the loading openings and the bottom supports of this product

They also design the radius of the tank, the dimensions and the shape of the required parts.

Then predict and check the amount of load on them and using calculations

and related software, the best and most appropriate height and thickness of the belt

will choose

In some cases, employers choose belt, type of grating, mesh or dimensional design

And the geometric shape of this product is left to the manufacturer.

In this case, the most optimal and solid plan should be created in addition to responding

To have a significant effect on the customer's needs, on the speed of manufacturing and the price of this production product.

Technical specifications of the grating product

This product is the result of the connection and collision of carrier belts and connectors

It is a network in each other.

In general, three types of grating are produced:

1. Belt in belt

2. Belt in half belt

3. Belt in the rebar (four sides twisted)

Grating product production

This product is the same metal grid or grid plate made by co2 welding

and machined belt punches, to specified sizes according to the designer

And construction drawings, produced and then using hot galvanized coating, electroplating

In addition to the beauty of appearance, this product will be resistant to scratches

and increase corrosion.

Hekmat Polad Khorgam company with trust in God and more than a decade of experience of committed personnel

The field of design, manufacture and production of galvanized products (mesh plates), metal stairs and structures

successful cooperation with large oil, gas, petrochemical and construction companies

And has had a pension and hopes to rely on knowledge and up-to-date equipment

and made the country self-sufficient in providing various types of this product.

Carrier belt

In the design and manufacture of this product, always at both ends of the loading opening or supports

They specify the type of belt in question. which is called a carrier belt

And in industrial maps it is symbolized by a double arrow like the logo above the site

show

All the load on the grating is on the belts.

Therefore, choosing the thickness, height and length of the carrier belt has the greatest effect

in the resistance and strength of this product.

In this way, by increasing the thickness and height of the bearing belt, the amount of bearing load is increased

The grating has increased and on the other hand with the increase of the loading opening and its nature

The length of the carrier belt reduces the resistance of this product.

Grating connector (belt, half belt, rebar or quadrilateral)

They use the interface to create grating networks and stabilize the bearing belts.

The grating interface did not bear a special load and only kept the appearance of the product

and causes the grating spring to form.

Of course, the length of the interface increases, due to the increase in the number of load belts

Gritnig's strength increases

standards

The production of any industrial part is subject to compliance with relevant principles and standards.

Production and galvanized grating is not exempted from this law and subject to standards

It is an international greeting.

The manufacturing standard of this product is in accordance with ANSI MBG 531 & 532.

Also, the production part is plated according to ASTM A123 galvanizing standard.

In the introduced standard, things like the amount of welding, radiation tolerance

And the dimensions and tolerance of the product installation are explained.

as well

Saler Company Information